Close Menu

© 2024 Dr. Paul Lohmann GmbH & Co. KGaA

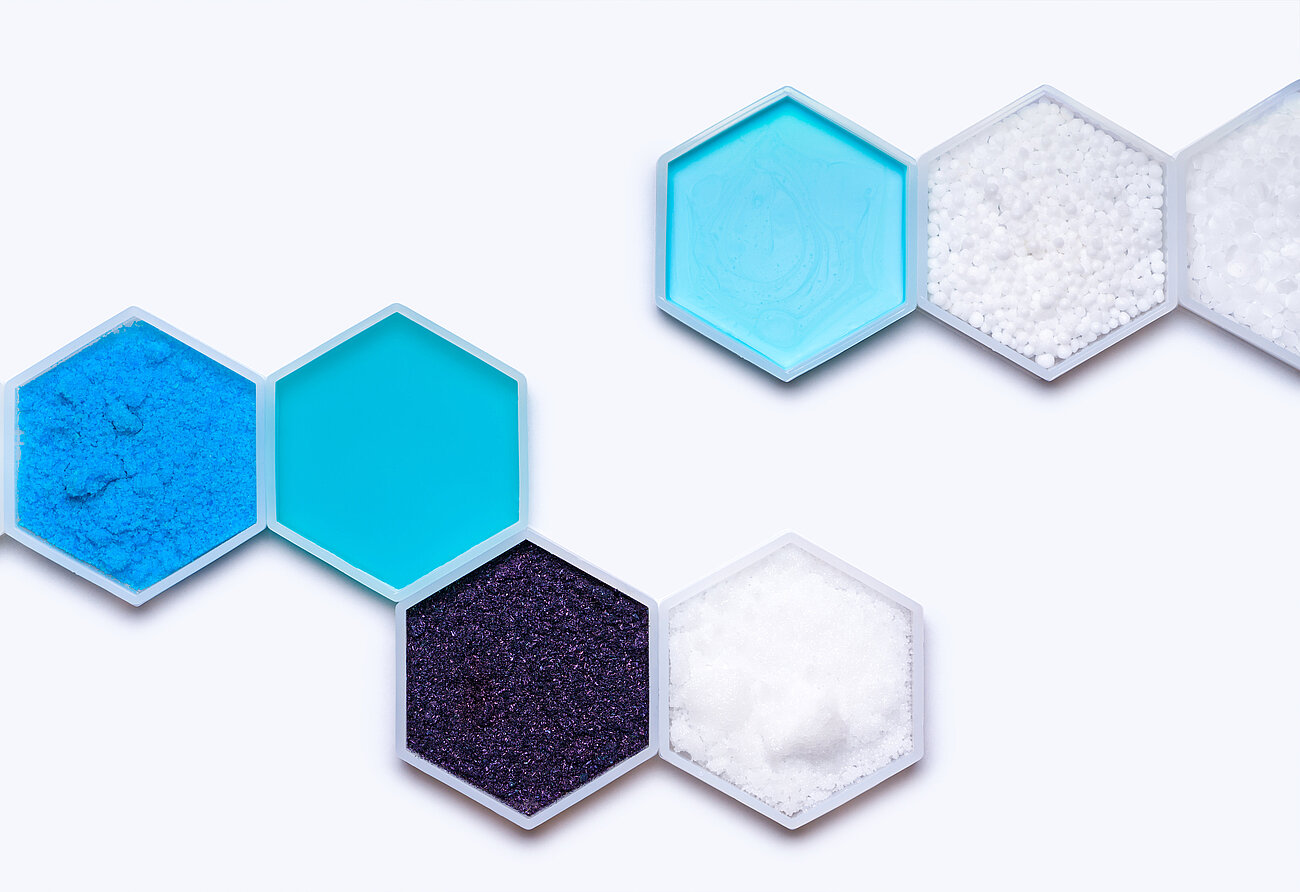

But we also modify the chemical and physical parameters of our products in manifold ways. In this way, we can tailor Mineral Salts to specific, individual needs.

We are able to combine a certain metal cation with a great number of different anions.

The effective component – the cation – remains the same; the properties of the compound are determined by the anion.

In addition, we modify in many ways

First and foremost, we make use of the Modular Chemical System ("MCS"), with which we combine anions and cations to create our Mineral Salts.

We are able to increase the mineral content of an end product for industrial applications, and for the use in food, nutritional supplements and pharmaceutical applications.

The parameters that we can adapt and vary include dissolution in water and increased solubility of our products.

We also offer modifications of the pH-value of products.

We granulate our Mineral Salts to improve their product characteristics for further processing by our customers. For example, homogeneous particle distribution and good flow properties facilitate dosage during further processing. Moreover, granulated Salts produce less dust, minimizing material losses and making an important contribution to occupational health & safety.

For more information, click here.

Another form of physical product modification is micronization. We can mill our products to achieve very fine particle sizes down to 2 µm (d50). This increases the bioavailability of a Mineral Salt when applied in food or nutritional supplements. In other areas of application, micronization varies the solubility or suspension properties of a Mineral Salt.

For more information, click here.

We can adapt our products' bulk density to produce a Mineral Salt with an optimum weight-to-volume ratio for a given application.

In addition to the standard quality grades that conform to international pharmacopoeias or European and international food legislation, we offer special purity grades to satisfy our customers' specifications:

For more information, click here.

Special foods for infants and young children are fortified with a variety of Minerals to promote optimum growth and age-appropriate development. A sufficient intake of Calcium and Iron is hugely important in this connection.

Infant and follow-on formula is governed by special, particularly stringent limits on the heavy metal content, as stipulated by Regulation (EU) No. 1881/2006./p> Aluminium limits for Calcium Phosphate are laid down in Regulation (EU) No. 231/2012 on purity criteria for food additives. These limits must not be exceeded when using Calcium Phosphates in formula. Our Calcium Phosphates are 2.5 – 5 times lower than the maximum content.

Foods for special medical purposes (FSMPs) and pharmaceutical products are further applications where an especially low heavy metal content is essential.

As a manufacturer of Mineral Salts, we offer them in special, controlled, low heavy metal grades for these special product groups. This ensures that the heavy metal content of the resulting end products conforms to the EU regulations and pharmacopoeias relevant to our customers.

The special feature of our technical grades, in particular, is the high constancy of their chemical properties. What counts for our customers above all else is high process reliability, delivering reproducible results no matter how many batches are processed.

Our expertise in industrial applications ranges from the finishing of metal surfaces to the control of setting processes in construction chemicals, and covers use in the petrochemical, glass and ceramic and numerous other industrial fields.

Find the right product for your applications to fit your needs.

Sample Request

Product Finder

Contact